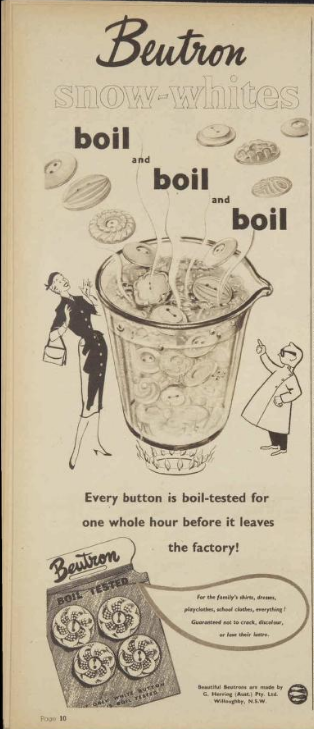

Boil Tested Buttons

Comments

If you're wondering about the term coppers in the ad, here's an explanation. https://en.wikipedia.org/wiki/Wash_copper

Posted by ges on 06/06/19 at 08:33 AM

The most popular casein-based plastics are notorious for warping. It happens most often with thick cross-sections, but I wouldn't be surprised if the differences across a button (thick rim, thin center) contributed to problems. With inconsistent purity of materials, still fairly primitive batch mixing and extruding, and no way to detect stresses in sheets prior to cutting, it isn't beyond the bounds of reason that someone thought boiling the buttons was a good way to sort out those which would curl. The fact that many people of the time still boiled their clothes, it played to good marketing.

Posted by Phideaux on 06/06/19 at 09:20 AM

The company that made these buttons got its start in something I never heard of -- sheep branding oil.

http://www.ausbuttonhistory.com/?page_id=251

http://www.ausbuttonhistory.com/?page_id=251

Posted by ges on 06/06/19 at 04:03 PM

Commenting is not available in this channel entry.

Category: Destruction | Domestic | Fashion | Advertising | Twentieth Century