The use of blood to make concrete

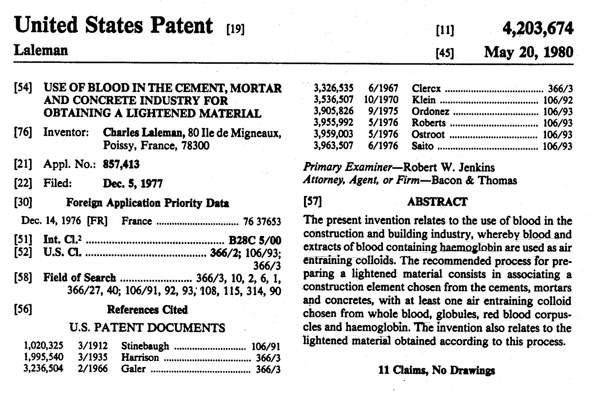

In 1980, Charles Laleman of France received a US patent (No. 4,203,674) for a technique for making concrete by mixing together cement with blood. His patent described a variety of different recipes one could use to create this blood concrete. For instance:

EXAMPLE 1

A light colloidal concrete is prepared by using:

a commercially available cement (cement CPA 400), a silico-calcareous sand graded no higher than 0.8 mm (the cement/sand mass ratio being equal to 1), whole blood powder of animal origin, a colloid, and mixing water in variable proportions.

The various constituents are mixed by means of a mixer working between 100 and 600 r.p.m.

A light colloidal concrete is prepared by using:

a commercially available cement (cement CPA 400), a silico-calcareous sand graded no higher than 0.8 mm (the cement/sand mass ratio being equal to 1), whole blood powder of animal origin, a colloid, and mixing water in variable proportions.

The various constituents are mixed by means of a mixer working between 100 and 600 r.p.m.

The advantage of using blood, Laleman argued, was that the oxygen in it produced a lighter concrete.

Curiously, Laleman acknowledged that the idea of using blood to make concrete wasn't in any way new. He cited a variety of earlier patents, such as US patent 1,020,325 from 1912 which described mixing blood into concrete. And, in fact, the technique of using blood to make concrete was even practiced by the ancient Romans.

What made Laleman's technique unique (and therefore patentable) was apparently that he used it specifically to lighten the concrete, rather than to color it or to make it more porous. That seems like a rather fine distinction to me, but it was enough to earn him a patent.

Laleman's list of earlier patents includes another oddity. He refers to US Patent No. 3,536,507 (from 1970) which describes making concrete by combining cement with "an admixture which is derived from the fermentation liquor resulting from the aerobic fermentation of liquid carbohydrates, e.g., molasses from beet or cane sugar, corn, wheat or wood pulp." That sounds like a fancy way of saying they were mixing cement with beer.

Comments

I don't remember blood being mentioned specifically, but many years ago, someone suggested building a machine that made small slugs of concrete, with each one having a slightly different concentration of an additive (ground burlap, insect exoskeletons, and molasses were examples). The machine would then monitor them during curing and do a test or two.

The basic idea was it might be a huge waste of money, but it might also reveal something no one would have ever predicted because reality is so much more messily fun than science would have you believe.

The basic idea was it might be a huge waste of money, but it might also reveal something no one would have ever predicted because reality is so much more messily fun than science would have you believe.

Posted by Phideaux on 03/15/20 at 05:02 PM

I wonder what practical use a "lighter" concrete has in construction? I've always thought that porous concrete was less sturdy that the denser mixes.

Posted by KDP on 03/15/20 at 07:46 PM

https://theconstructor.org/concrete/lightweight-concrete/1670/

It does have less strength and durability than normal concrete, but it is still reasonably cheap, fireproof, and insulates.

It does have less strength and durability than normal concrete, but it is still reasonably cheap, fireproof, and insulates.

Posted by Phideaux on 03/15/20 at 08:25 PM

Thanks, Phideaux. That was very instructive. The moment I saw that photo of the concrete blocks I knew that I hadn't put enough thought into my question. My experience with concrete has been mainly with a bag of premix and water.

Posted by KDP on 03/16/20 at 09:13 AM

Commenting is not available in this channel entry.

Category: Engineering and Construction | Inventions | Patents | 1980s | Blood